Offre personnalisée sur demande ! – contactez-nous : rv@extrom.net

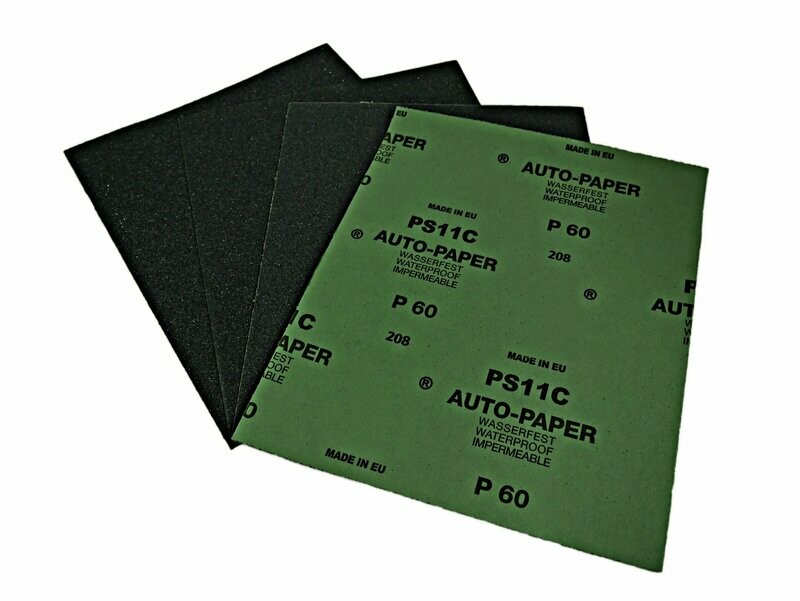

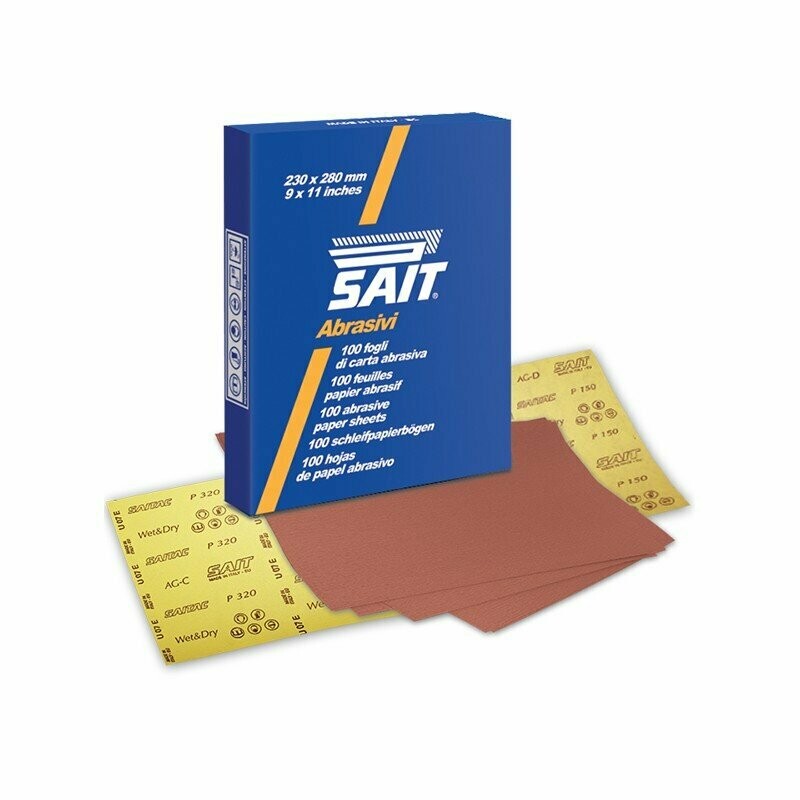

Papier

Feuilles abrasives avec support papier

Pour une utilisation à sec ou à l'eau.

Comment et pourquoi flexer ?

Que veut dire FLEXER ?

Rendre flexible ou plus souple.

Comment FLEXER ?

Prenez la feuille par les coins diagonalement opposés et glissez-la contre une arête droite et vive

pour «casser» la colle qui maintient les grains. Les grains resteront fixés mais «détachés» entre-eux.

Pourquoi FLEXER ?

Pour assouplir la feuille en lui gardant toutes ses qualités abrasives.

"Seules les feuilles dont le principe de fabrication repose sur l’électrodéposition des grains doivent être flexées. Les micro-abrasifs sont produits par coulée d’une émulsion abrasive sur le support, ils ne doivent pas être flexés."